Transformers are essential items and have many applications in human life. Understanding the structure and operating principles of transformers helps to use transformers more effectively. Through this article, let’s learn about the structure and operating principles of transformers with QNT Investment and Trading Services Joint Stock Company in the article below to make your use of transformers more effective.

1. What is a transformer?

A transformer (or transformer) is an electrical device used to change the voltage of an alternating current from one level to another (usually increasing or decreasing the voltage). It operates on the principle of electromagnetic induction, consisting of two coils of wire (primary coil and secondary coil) wound around a magnetic core. When an alternating current flows through the primary coil, a changing magnetic field is created and induces a current in the secondary coil, creating a voltage that is different from the original voltage.

2. The role of transformers

Transformers play an important role in the power system, helping to regulate voltage to transmit and distribute power over long distances without causing great loss, and then reduce the voltage for safe use in household and industrial electrical appliances.

Transformers are used to transmit and distribute power in the power system. They are also widely used in welding techniques, furnace equipment, radio engineering, in the field of measurement. in automatic devices, as a source for electrical and electronic equipment, in household appliances, etc.

The most common use of transformers is to convert 3-phase voltage down, usually the input voltage is 380V, the output voltage is 200V/220V, frequency 49-62 Hz.

3. Structure and operating principle of transformer

a. Structure

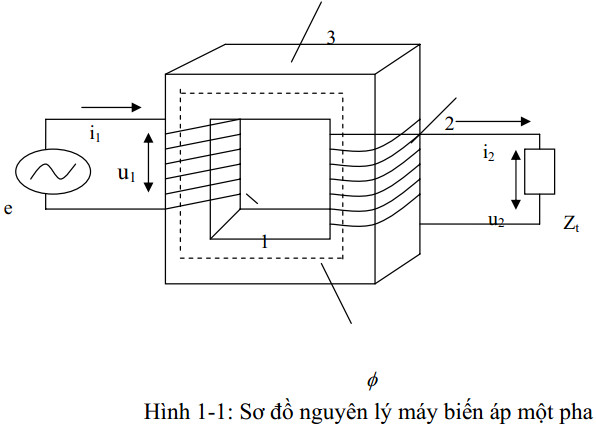

The transformer consists of two main parts: Steel core (silicon steel) and Winding wire (copper wire or aluminum wire).

The steel core of the machine is arranged from oriented steel sheets: Used to conduct the main magnetic flux of the machine, made from good magnetic conductive materials, usually electrical engineering steel or thin oriented steel sheets joined together. To reduce eddy currents in the steel core, people use electrical engineering steel sheets, two sides with insulating paint joined together to form a steel core.

Wound wire: The transformer winding wire, wrapped around the steel core, is made from copper wire or aluminum wire, there are round wires, flat wires, the outside of the wire is covered with one or more layers of insulating paper. Made from copper or aluminum wire with round or rectangular cross-section, the outside of the wire is covered with insulation:

– Includes two coils: the primary coil has N1 turns and the secondary coil has N2 turns. The transformer core consists of many thin iron sheets insulated together to avoid Eddy currents and increase the magnetic flux through the circuit.

– The number of turns in the two coils must be different, depending on the task of the machine, N1 > N2 or vice versa.

– The primary coil is connected to the AC circuit and the secondary coil is connected to the load that consumes electricity.

The transformer has a relatively simple structure, the manufacturing of the transformer is also much simpler than the voltage stabilizer, because the nature is only to convert the current, no control circuit is needed. Therefore, the machine operates very durably, rarely breaks down, and has a long life.

b. Operating principle

The transformer operates according to 2 physical phenomena:

– The current running through the wire creates a magnetic field (magnetic field)

– The change in magnetic flux in the coil creates an induced voltage (electrical induction). The current is created in the primary coil when connected to the primary voltage, and a changing magnetic field in the iron core. This changing magnetic field creates a secondary voltage in the secondary circuit. Thus, the primary voltage can change the secondary voltage through the magnetic field. This change can be adjusted through the number of turns on the iron core.

Transformers are usually cooled by air, ventilation slots, and heat sinks. There are large capacity transformers cooled by oil, by pouring oil into the transformer core. When the oil is left for a long time and has deposits, the deposits can be filtered out or replaced with new oil.

To reduce the loss dP = I2.R on the transmission line, there are two options:

– Option 1: Reduce the resistance R of the line (R = r.l/S)- To reduce M R, we increase the cross-section of the conductor S, which means increasing the mass of the conductor, the support pillars for the line, the cost of building the transmission line is very large (this option is not economical).

– Option 2: Reduce the current I running on the transmission line.

To reduce I, we must increase the voltage, we need to use a booster because for the transformer U1I1 = U2.I2 (this solution is more economical and effective)

4. Transformer classification

There are many types of transformers, but the most popular are autotransformers and isolation transformers.

On the market today, there are many companies that produce transformers with different brands such as Lioa, Standa, Vitenda transformers… Customers who need transformers should refer to the product specifications to understand the real value of the product. Thus, customers will buy high-quality products at a reasonable price – true to the real value, avoiding having to buy high-priced products when buying additional brand value for the product.

If you have any questions about transformers, you can contact us immediately for free advice and answers. Thank you and wish you effective use of the machine.

Watch more:

Measures to prevent incidents when using electrical equipment

Benefits of wall sockets you may not know

Discover about the structure of the Busway

For more details, please contact

QNT INVESTMENT AND TRADING SERVICES COMPANY LIMITED

Showroom address: TM07 My Dinh Pearl 1, No. 1 Chau Van Liem Street, Phu Do Ward, Nam Tu Liem District, Hanoi

Hotline: 0977.566.348

QNT is always happy to provide free consultation on lighting equipment.

QNT sincerely thanks and looks forward to working with you!